News

SpaceX installs rocket-catching arms on Starship’s Florida launch tower

SpaceX has installed a pair of rocket-catching arms on a tower meant to support the first East Coast launches of its next-generation Starship rocket.

The company has been building the second of several planned Starship launch sites for more than three years. Ironically, work on that pad began before the company started building the pad that will actually support Starship’s first orbital launch attempts. Located a stone’s throw from the Gulf of Mexico in Boca Chica, Texas, the first iteration of SpaceX’s Starbase orbital launch site (OLS) is nearly complete and could host Starship’s orbital launch debut in a matter of months. SpaceX began constructing Starship’s Texas launch site in earnest in late 2020.

SpaceX broke ground on Starship’s first Florida OLS in late 2019. But the company went on to radically redesign the rocket and its ground systems, forcing it to entirely abandon about a year of work by the end of 2020. In late 2021, SpaceX finally began constructing the second iteration of Starship’s first Florida pad. OLS #2 is still colocated at Kennedy Space Center’s LC-39A pad, which SpaceX leases from NASA. Pad 39A is the only site currently capable of launching SpaceX’s Crew Dragon astronaut spacecraft or Falcon Heavy rocket, which has complicated its plans to use the same pad for Starship.

The update that's rolling out to the fleet makes full use of the front and rear steering travel to minimize turning circle. In this case a reduction of 1.6 feet just over the air— Wes (@wmorrill3) April 16, 2024

Because of NASA’s trepidation at the thought of a Starship failure indefinitely delaying SpaceX from completing its Crew Dragon or Falcon Heavy contracts for the agency, the company deprioritized Starship’s Florida pad, slowing progress. SpaceX has, nonetheless, made significant progress. In 13 months, SpaceX has created foundations, modified one of Pad 39A’s giant spherical tanks to store cryogenic methane, installed miles of plumbing, built and assembled a second skyscraper-sized Starship launch tower, installed the legs of the pad’s ‘orbital launch mount’ or OLM, installed a water deluge system at the base of the OLM, assembled most of the OLM’s donut-like mount offsite, constructed a new supersized storage tank, and delivered a forest of smaller storage tanks.

Most recently, SpaceX finished building a giant pair of steel arms, transported the arms to Pad 39A, attached them to a wheeled carriage, and installed the structure on Starship’s Florida launch tower. SpaceX employees have nicknamed the arms “chopsticks,” and those arms are integral to what CEO Elon Musk calls “Mechazilla”. Mechazilla refers to the combined launch tower and arms, which SpaceX has designed to grab, lift, stack, and fuel both stages of Starship.

Mechazilla’s simplest part is a third arm that is vertically fixed in place but capable of swinging left and right. The swing arm contains plumbing and an umbilical device that connects to Starship’s upper stage and supplies propellant, gas, power, and connectivity. The tower’s ‘chopsticks’ are far more complex. Giant hinges connect the pair of arms to a carriage that grabs onto three of the tower’s four legs with a dozen skate-like appendages. Those skates are outfitted with wheels, allowing the carriage to roll up and down tracks built into the tower’s legs.

The carriage, which also carries the complex hydraulic systems that allow its bus-sized arms to move, is connected by steel cable to a heavy-duty “draw works” capable of hoisting the multi-hundred-ton assembly up and down the tower. Once finished, the Florida tower’s arms will be able to precisely lift, maneuver, stack, and de-stack Starship and Super Heavy even in relatively windy conditions. At some point in the future, SpaceX may attempt to use its towers and chopsticks to catch Starships and Super Heavies out of mid-air and speed up reuse.

Set to be the largest, most powerful, and most capable rocket in history, Starship is primarily built out of steel and designed to be fully reusable. SpaceX has a long way to go to demonstrate that the 120-meter-tall (~390 ft) rocket can reach orbit, let alone be reused. In theory, though, Starship is meant to launch up to 150 metric tons (330,000 lb) to low Earth orbit (LEO) while still allowing for the recovery and reuse of its suborbital Super Heavy booster and orbital Starship upper stage.

If SpaceX can achieve those figures, Starship will be the most capable rocket in history even with the major performance penalties that full reusability entails. Saturn V, the most capable rocket ever flown, was fully expendable and could launch up to 118 metric tons (~260,000 lb) into orbit.

Due to NASA’s concerns about the risks that Starship launches from Pad 39A could pose to SpaceX’s Falcon and Dragon operations at the same site, the company’s next-generation rocket may have to wait until 2024 or 2025 for its first Florida launch. With the first Florida Mechazilla now close to completion, it’s likely that Pad 39A’s Starship launch site will be ready and waiting as soon as NASA gives SpaceX the green light.

Investor's Corner

Tesla Board member and Airbnb co-founder loads up on TSLA ahead of robotaxi launch

Tesla CEO Elon Musk gave a nod of appreciation for the Tesla Board member’s purchase.

Tesla Board member and Airbnb Co-Founder Joe Gebbia has loaded up on TSLA stock (NASDAQ:TSLA). The Board member’s purchase comes just over a month before Tesla is expected to launch an initial robotaxi service in Austin, Texas.

Tesla CEO Elon Musk gave a nod of appreciation for the Tesla Board member in a post on social media.

The TSLA Purchase

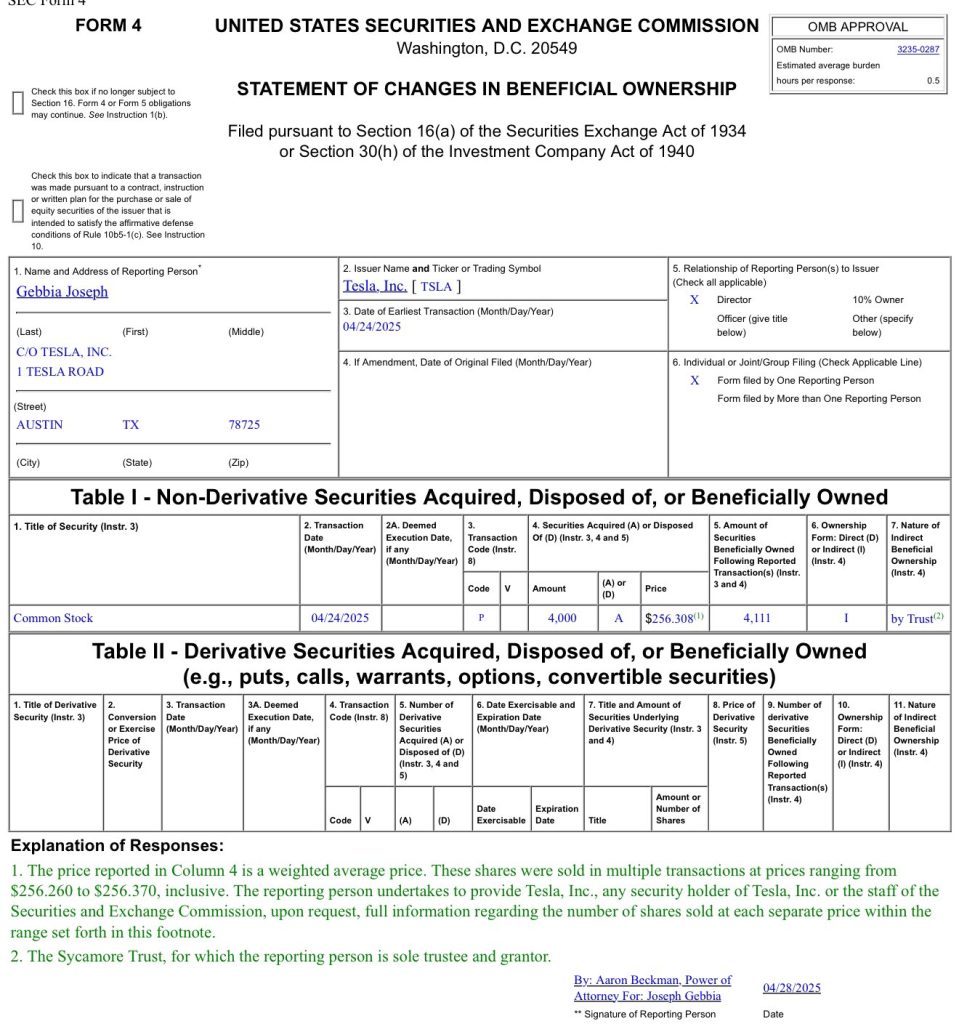

As could be seen in a Form 4 submitted to the United States Securities and Exchange Commission (SEC) on Monday, Gebbia purchased about $1.02 million worth of TSLA stock. This was comprised of 4,000 TSLA shares at an average price of $256.308 per share.

Interestingly enough, Gebbia’s purchase represents the first time an insider has purchased TSLA stock in about five years. CEO Elon Musk, in response to a post on social media platform X about the Tesla Board member’s TSLA purchase, gave a nod of appreciation for Gebbia. “Joe rocks,” Musk wrote in his post on X.

Gebbia has served on Tesla’s Board as an independent director since 2022, and he is also a known friend of Elon Musk. He even joined the Trump Administration’s Department of Government Efficiency (DOGE) to help the government optimize its processes.

Just a Few Weeks Before Robotaxi

The timing of Gebbia’s TSLA stock purchase is quite interesting as the company is expected to launch a dedicated roboatxi service this June in Austin. A recent report from Insider, citing sources reportedly familiar with the matter, claimed that Tesla currently has 300 test operators driving robotaxis around Austin city streets. The publication’s sources also noted that Tesla has an internal deadline of June 1 for the robotaxi service’s rollout, but even a launch near the end of the month would be impressive.

During the Q1 2025 earnings call, Elon Musk explained that the robotaxi service that would be launched in June will feature autonomous rides in Model Y units. He also noted that the robotaxi service would see an expansion to other cities by the end of 2025. “The Teslas that will be fully autonomous in June in Austin are probably Model Ys. So, that is currently on track to be able to do paid rides fully autonomously in Austin in June and then to be in many other cities in the US by the end of this year,” Musk stated.

News

Stellantis unveils solid-state battery for EVs

Stellantis validated solid state battery cells for EVs: ultra-dense, fast-charging, and AI-optimized. Launching demo fleet by 2026.

Stellantis N.V. and Factorial Energy have validated Factorial’s automotive-sized FEST® solid-state battery cells, a major milestone for next-generation electric vehicle (EV) batteries. The breakthrough positions Stellantis and Factorial to advance EV performance with lighter, more efficient batteries.

“Reaching this level of performance reflects the strengths of our collaboration with Factorial.

“This breakthrough puts us at the forefront of the solid-state revolution, but we are not stopping there. We continue working together to push the boundaries and deliver even more advanced solutions, bringing us closer to lighter, more efficient batteries that reduce costs for our customers,” said Ned Curic, Stellanti’s Chief Engineering and Technology Officer.

The 77Ah FEST® cells achieved an energy density of 375Wh/kg, supporting over 600 cycles toward automotive qualification. Unlike lithium-ion batteries, these solid-state cells charge from 15% to over 90% in 18 minutes at room temperature and deliver high power with discharge rates up to 4C. Factorial’s AI-driven electrolyte formulation enables performance in temperatures from -30°C to 45°C (-22°F to 113°F), overcoming previous solid-state limitations.

“Battery development is about compromise. While optimizing one feature is simple, balancing high energy density, cycle life, fast charging, and safety in an automotive-sized battery with OEM validation is a breakthrough,” said Siyu Huang, CEO of Factorial Energy. “This achievement with Stellantis is bringing next-generation battery technology from research to reality.”

The collaboration optimizes battery pack design for reduced weight and improved efficiency, enhancing vehicle range and affordability. Stellantis invested $75 million in Factorial in 2021 and plans to integrate these batteries into a demonstration fleet by 2026. This fleet will validate the technology’s real-world performance, a critical step toward commercialization.

The milestone aligns with Stellantis’ push for sustainable EV solutions, leveraging Factorial’s disruptive technology to meet the rising demand for high-performance batteries. As the companies refine pack architecture, the validated cells promise faster charging and greater efficiency, potentially reshaping the EV market. With the demonstration fleet on the horizon, Stellantis and Factorial are poised to lead the solid-state battery push, delivering cost-effective, high-range EVs to consumers.

News

Tesla China vehicle registrations rise 51% in April’s fourth week

In the week ending April 27, Tesla China saw 10,300 new vehicle registrations.

Tesla China’s new vehicle registrations saw a notable rise in the week of April 21-27, 2025. Over the week, the electric vehicle maker’s registrations saw an impressive 51% week-over-week rise, suggesting that domestic vehicle deliveries are on the rise once more.

Tesla China Results

In the week ending April 27, Tesla China saw 10,300 new vehicle registrations. This represents a notable rise from the company’s registration numbers in the past weeks of April. For context, Tesla China saw 3,600 registrations in the week ending April 6, 5,400 registrations in the week ending April 13, and 6,780 registrations in the week ending April 20, 2025.

Considering that April is the first month of the second quarter, expectations were high that Tesla China was allocating Giga Shanghai’s output for vehicle exports. With 10,300 registrations in the week ending April 27, however, it would appear that the company’s domestic deliveries are picking up once more.

Tesla China does not report its weekly sales figures, though a general idea of the company’s overall perforce in the domestic auto sector can be inferred through new vehicle registrations. Fortunately, these registrations are closely tracked by industry watchers, as well as some local automakers like Li Auto.

Tesla Model 3 and Model Y in Focus

Tesla China produces the Model Y and Model 3 in Giga Shanghai. Both vehicles are also exported from China to foreign territories. As per industry watchers, it would appear that both the Model 3 and Model Y saw an increase in registrations in the week ending April 27.

The Model 3, for one, appears to have seen 3,200 registrations in the week ending April 27, a 14% increase from the 2,800 that were registered in the week ending April 20. For context, Tesla China saw just 1,500 new Model 3 registrations in the week ending April 13 and 1,040 registrations in the week ending April 6.

The Model Y, on the other hand, saw 7,100 registrations in the week ending April 27. That’s a 77.5% increase from the 4,000 that were registered in the week ending April 20. Tesla also saw 3,900 registrations in the week ending April 13, and 2,540 registrations in the week ending April 6, 2025.

-

News1 week ago

News1 week agoTesla’s Hollywood Diner is finally getting close to opening

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla doubles down on Robotaxi launch date, putting a big bet on its timeline

-

News4 days ago

News4 days agoTesla is trying to make a statement with its Q2 delivery numbers

-

News2 weeks ago

News2 weeks agoTesla’s top investor questions ahead of the Q1 2025 earnings call

-

News2 weeks ago

News2 weeks agoUnderrated Tesla safety feature recognized by China Automotive Research Institute

-

News2 weeks ago

News2 weeks agoTesla reveals its Q1 Supercharger voting winners, opens next round

-

News2 weeks ago

News2 weeks agoTesla police fleet saves nearly half a million in upkeep and repair costs

-

Investor's Corner7 days ago

Investor's Corner7 days agoLIVE BLOG: Tesla (TSLA) Q1 2025 Company Update and earnings call